POMEGRANATE / CHERRY PROCESSING LINES (for Juice Industry)

up to 20-25 tons/h of fruit input capacity

Pomegranate

Sourcherry

Grape

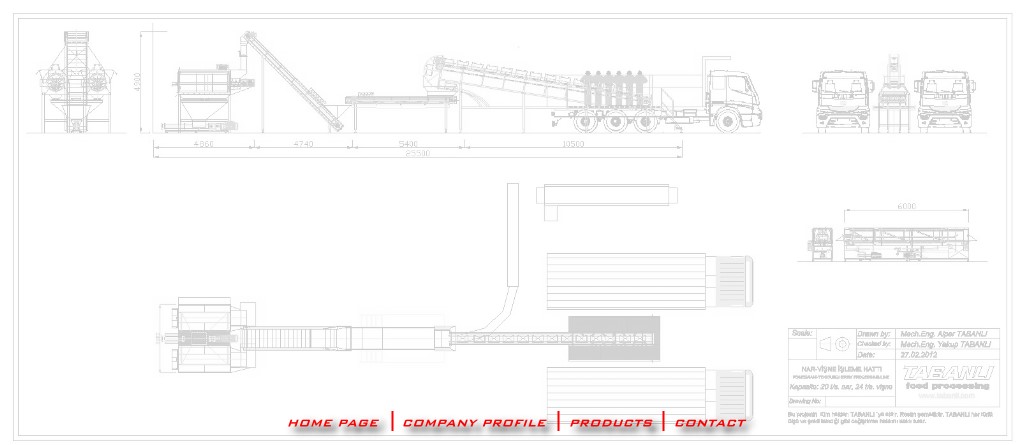

20tons/h of Pomegranate Depoding and 25tons/h of Cherry Destemming Line (2012, Isparta-Turkey) Crate Feeder-Discharger Unite, Sorting Conveyor, Elevator, Pomegranate Aril Separator / Cherry Destemmer TPAS01 machines, Mohnopump and Crate Washer.

10tons/h of Pomegranate Depoding and 12tons/h of Cherry Destemming Line (Denizli-Turkey) Sorting Conveyor, Elevator, Pomegranate Aril Separator / Cherry Destemmer TPAS01 machine, Mohnopump and Crate Washer.

Tannin is available at peels of pomegranate and tannin gives bitterness to juice. Pomegranate Aril Separator / Cherry Destemmer Model.TPAS01 separates arils by exploding of pomegranate pods without cutting. So tannin addition to juice is minimized. Also, Our TPAS01 machine can both separate Pomegranate arils and stem of cherries without any change. Minimum leakage provided. Our TPAS01 machine is the best choice in the world for your juice production. Model.TCD01 and TCD02 machines are just can be use for only destemming of cherries.

Output Pomegranate arils

and peels

10tons/h of Pomegranate Depoding and 12tons/h of Cherry Destemming Line (2010, Mersin-Turkey) Sorting Conveyor, Elevator, Pomegranate Aril Separator / Cherry Destemmer TPAS01 and Mohnopump. (2011, Erzincan-Turkey) Pomegranate Aril Separator / Cherry Destemmer TPAS01 and Mohnopump. (2012, Eregli/Konya-Turkey) Elevator, Pomegranate Aril Separator / Cherry Destemmer TPAS01 and Mohnopump. (2012, Karacabey/Bursa-Turkey) Pomegranate Aril Separator / Cherry Destemmer TPAS01 and Mohnopump.

Pomegranate Aril Separator (De-Podder) / Cherry Destemmer

Pomegranate Input Capacity: up to 10 tons/h

Sourcherry Input Capacity: up to 12 tons/h

24tons/h Cherry Destemming Line (1998, Civril/Denizli-Turkey) Sorting Conveyor, Elevator, Cherry Destemmers Model.TCD02 and Mohnopump.

Cherry Destemmer

Input Capacity: up to 4 tons/h

Output Cherry destemmed

and stems

Input Capacity: up to 8 tons/h

Crate Feeder-Discharger

This machine feeds processing line regular, so line`s machines reach up maximum efficiency.

Sorting Conveyor (Modular plastic belt, with shower)

Elevator (Modular plastic belt, with shower)

Panel includes electrical materials, alarm, diagram with led and variable speed control inverters of the all line`s machines and conveyors.

Crate Washing and Transporting Unite

We can provide lots of solution for crate washing systems depends on your capacity and dirtness.

Washer is used for pomegranate washing preferably, but not for sourcherry. Sourcherry should be have shower on the sorting conveyor and elevator for washing.

Electrical Control Panel

Crate Washer (Single line, 1500crates/h) Model.TCW60Tspw

Sourcherry mash is heated up to 75C from 20-25C input temperature by tube in tube type exchanger. Exchanger `s outer tubes for heater media transfer. Saturated Steam or Superheated water at 105C as Heater media. Also, You want us optional Superheated water crating and circulating unit consists of steam-water exchanger, proportional temperature controller, centrifugal pump water circulator etc.

Crate Washer (Single Line, 800 crates/h) Model.TCW45T

Crate Washer (Double line, 3000crates/h) Model.TCW90TDspw

Mash Heater / Coller Exchanger (Tube in tube)

Mash Tanks