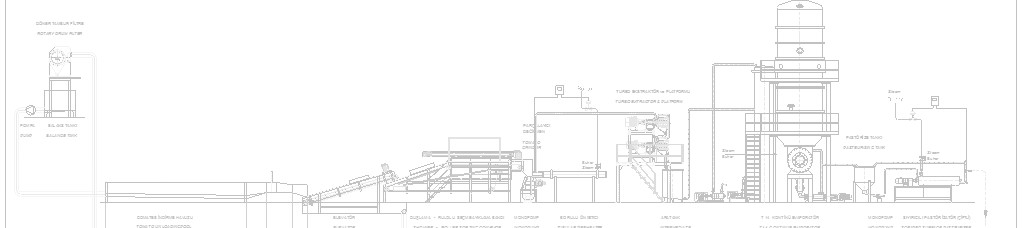

TOMATO PROCESSING and TOMATO PASTE PRODUCTION LINES

Output capacities up to 60 tons/day of tomato paste (28-30% brix) / Input capacities up to 20 tons/h of tomatoes (5% brix)

pneumatic controlled channel gate system

Rotary Drum Filter

for filtering of circulated pool water

Channel

for transporting of tomatoes with water

Reception Pool

Rotary Drum Filter and Water circulating Unit

Washer

Roller Sorting Conveyor

can be manufactured with elevating section with shower and waste conveyor

IMost of Equipment can be used also for pepper paste production.

Elevator with st. steel product supported belt

Elevator is used for elevating and dewatering of tomatoes come from Reception pool with water.

Crusher

Hammer Mill

It is used for milling of tomatoes and peppers.

It is used for milling of various product such us tomatoes, peppers, apple, even carrot.

Elevator with modular system plastic belt

Water Collecting and Circulating Tank under Elevator

Chopper

It is used for milling of tomatoes and fruit without stones. It including rotating circular knives.

Tubular Pre-Heater for Cold-Break Process

Enzymatic Deactivator for Hot-Break Process

Turbo Extractor

It is used for getting puree / pulp from tomatoes, fruit without stones.

Capacity is increased up with hot-break (HB) process.

Model. TTE30 - up to 30tons/h of tomatoes (HB) with 1,2mm & 0,8mm sieves

Model. TTE15 - up to 15tons/h of tomatoes (HB) with 1,2mm sieve

Evaporator

Evaporator

Model. TE7 - up to 180 tons/day of tomatoes (5% brix) processing capacity

2 Vacuum Boules & Preconcentrator up to 45-50 tons/day of tomatoes (5% brix) processing capacity

Model. TTE100 - up to 100tons/h of tomatoes (HB) with 2,0mm & 1,2mm sieves

Evaporator

2 Vacuum Boules - up to 36-40 tons/day of tomatoes (5% brix) processing capacity

Model. TE14 - up to 360 tons/day of tomatoes (5% brix) processing capacity

Model. TTE50 - up to 50tons/h of tomatoes (HB) with 1,2mm sieve

Pulper - Finisher

Model TPF5 - up to 5tons/h of tomatoes (CB) with 1,5mm & 0,8mm & 0,6mm sieves

Model TPF3 - up to 3tons/h of tomatoes (CB) with 1,5mm & 0,8mm sieves

Evaporator

3 Vacuum Boules - up to 54-60 tons/day of tomatoes (5% brix) processing capacity

Evaporator

4 Vacuum Boules & Preconcentrator - up to 90-100 tons/day of tomatoes (5% brix) processing capacity

By-pass Tank

Tubular Pasteuriser (multitube)

Scraped Surface Pasteuriser

Capacity up to 1500kg/h of tomato paste.

Tunnel Pasteuriser & Cooler

Tubular Pasteuriser / Steriliser (tube in tube) and Holder

Ketch-up Production Line

It is used for producing of ketchup from tomato paste (28-30% brx). It consists of Aseptic Barrel Discharger, Preparing Tank, Vacuum Boule, Holding Tank, Homogeniser, Deaerator (as optional with Pre-Heater without Vacuum Boule Systems), Tubular Pasteuriser / Steriliser - Holder and optional Tubular Cooler (without Hot-filled process)