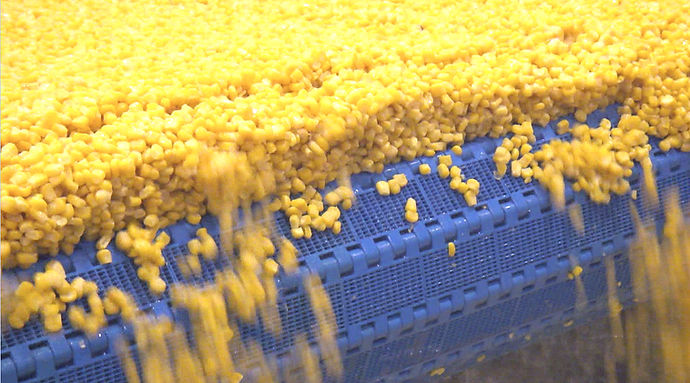

Blanching & Cooling

for Frozen Food and Canned Food Sectors

Processing Capacity

from 1 ton/hr up to 15 tons/hr of pea grain based

TABANLI combines his expertise in the food processing equipment with creative and high technology for your processing requirements, blanching up as well as cooling down.

Elevate Your Output: Precision-Engineered Blanching and Cooling for Global Food Standards

In the highly competitive Frozen and Canned Food markets, product quality and operational efficiency are non-negotiable. At TABANLI FOOD PROCESSING, we don't just supply machinery; we deliver advanced preservation technology designed to maximize your product’s shelf life, color, and nutritional integrity.

Our comprehensive range of Blanchers and Coolers is the definitive choice for processors requiring both reliability and massive throughput.

Unmatched Capacity & Versatility:

We offer solutions tailored for every scale, with verified processing capacities ranging from 1 ton/hr up to an impressive 15 tons/hr (pea grain equivalent). Our core expertise spans:

-

Spraying Belt Blancher-Coolers (TSBBC Series): Featuring direct steam-heated hot water spraying and a dual-stage cooling system (fresh/chilled water spray + air cooling), these systems deliver fast, uniform processing and precise temperature control. Ideal for frozen food sector and high-volume operations requiring superior efficiency.

-

Immersion Belt Systems (TIBBC Series): Perfect for products requiring full submersion, these robust units ensure consistent heat transfer, preserving product texture and quality.

-

Screwed Drum & Submerging Blanchers (TSDB Series): Engineered for specific product characteristics, offering continuous, gentle, and reliable blanching for various grains and vegetables.

The TABANLI Advantage:

Every TABANLI system is precision-engineered to provide:

-

Enzyme Deactivation Perfection: Achieving the ideal D-value for product stabilization and maximum nutritional retention.

-

Minimized Water Consumption: Our smart spraying and cooling designs significantly reduce operational costs and environmental impact.

-

Durability & Hygiene: Constructed from premium materials for long service life and effortless sanitation, meeting the most rigorous global food safety standards.

Partner with TABANLI to integrate future-proof technology into your processing line. Achieve greater output, better quality, and a definitive competitive edge. Contact us today to design your optimal processing solution.

Meet The Blancher & Coolers

%20-%20front.jpg)