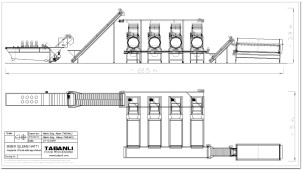

PEPPER PROCESSING LINES

from 2 ton/h up to 10 tons/h of kapija pepper processing capacity

Slicer Dicer Cutter

It is used for cutting of a wide variety of products up to diameter 200mm to slices, strips and dices at high capacities. First, Slicing knife cuts products required thickness, then circular knives cut the slices into strips and finally crosscut knives` spindle cuts the strips into dices. Slicing thickness can be adjusted between 2mm and 13mm.

Pepper Corer / Halver

up to 2000kgs/h

Pepper Coring / Halving and Seed Removing Line

It is first level of frozen sliced/strip/diced pepper producing and pepper paste producing. This line consists of Bulk Feeder, Brush Washer or Universal Washer, Pepper Corer / Halver, Drum Seed Separator and Vibrators, Elevators & Conveyors between those. All machines are made of AISI 304 Cr-Ni st. steel and non-corrosive materials.

Vibratory Seed Separator

Brush Washer

Drum Seed Separator

For washing of very dirty peppers.

kapija pepper

Vibratory Distributors

Bulk Feeder

Universal Washer

Pneumatic (Fan) Separator / Air Cleaner

These vibrators are used for feeding of Pepper Corer / Halver machines arranged in a row at high capacity processing lines.

It is used for regular feeding of the line and getting maximum efficiency.

It is used for the best washing of all kind of vegetables.

It is used for separating of unwanted materials like trash, dust, leaves etc. in product.