Sun-dried Tomato Processing

for Canned Food Sector

Sun-dried Tomato Processing

Main Levels

Pre-Processing before sun drying

Washing

Inspection

Dividing

Sulfurization

Draining

Processing after sun drying

Dry Cleaning

Inspection

Washing

Dewatering

Flavouring & Oiling

Sun-Dried Tomato Processing Solutions

From Field to Table: Excellence in Every Slice

Transform your harvest into premium gourmet products with our state-of-the-art sun-dried tomato processing lines. We offer a dual-stage system designed to preserve the vibrant color, rich aroma, and nutritional value of your tomatoes while ensuring the highest hygiene standards.

1. Pre-Processing: Setting the Standard for Quality Before the sun works its magic, we prepare your produce for perfection:

-

Washing: Gentle yet thorough cleaning to remove field debris.

-

Inspection: Manual and automated sorting to select only the finest tomatoes.

-

Dividing: High-precision cutting for uniform drying results.

-

Sulfurization: Preserving that iconic deep red color and extending shelf life.

-

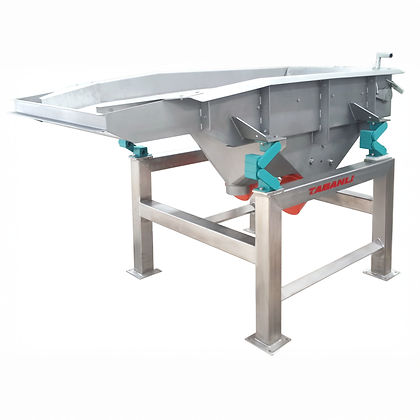

Vibrating Desulfurization: Advanced vibration technology to ensure optimal sulfur levels and product consistency.

2. Post-Drying Processing: Refining the Gourmet Experience Once dried, we turn sun-kissed tomatoes into shelf-ready delicacies:

-

Dry Cleaning: Removing any physical impurities gathered during the drying process.

-

Inspection: A secondary quality check to ensure only flawless pieces proceed.

-

Washing: Rehydrating and cleaning the dried fruit to achieve the perfect texture.

-

Dewatering: Removing excess moisture to prep for seasoning.

-

Flavouring & Oiling: The final touch—infusing with herbs and premium oils for a rich, Mediterranean taste profile.

_edited.jpg)