A Success Story: "Why We Chose TABANLI Vacuum Boule Type Concentrator?"

- 6 hours ago

- 3 min read

Introduction: Below is a candid dialogue between a food facility manager and our engineering team regarding quality concerns and past technical failures.

Prospective Client: "Let’s be honest; my biggest fear is quality standards. In our previous system, products were rejected and recalled because HMF (Hydroxymethyl Furfural) values were too high. It was a financial disaster and a loss of prestige. Will we experience this HMF nightmare again with your system?"

Response: High HMF is usually the result of uncontrolled heat transfer and insufficient vacuum. We have been manufacturing these machines since 1974. Our system operates at low temperatures under high vacuum. We concentrate your product rapidly without burning it, avoiding caramelization and preserving its natural aroma. By boiling at 56-58 °C under a vacuum gauge pressure of 600-650 mmHg, we keep HMF values well below international limits, strengthening your position in export markets.

Prospective Client: (Looking surprised at the technical specs) "Wait a second, I see some figures here but I find them hard to believe. You’ve stated an evaporation capacity of 500 liters/hour for the 130 cm diameter ball and 250 liters/hour for the 100 cm version. My old system also had this 130cm diameter, but I couldn't even achieve half of these values, maybe only a third. Are these numbers really possible?"

Response: We understand your skepticism because the efficiency gap between us and standard machines is exactly here. Our secret lies in the perfect spherical form and our advanced vacuum units. What you describe as 'reaching a third at best' is what we achieve at three times of your capacity every single day, without stressing the product.

Prospective Client: "What about durability? The body sheets of our old machines cracked within a few years; we were constantly welding and patching them. Why are your tanks different?"

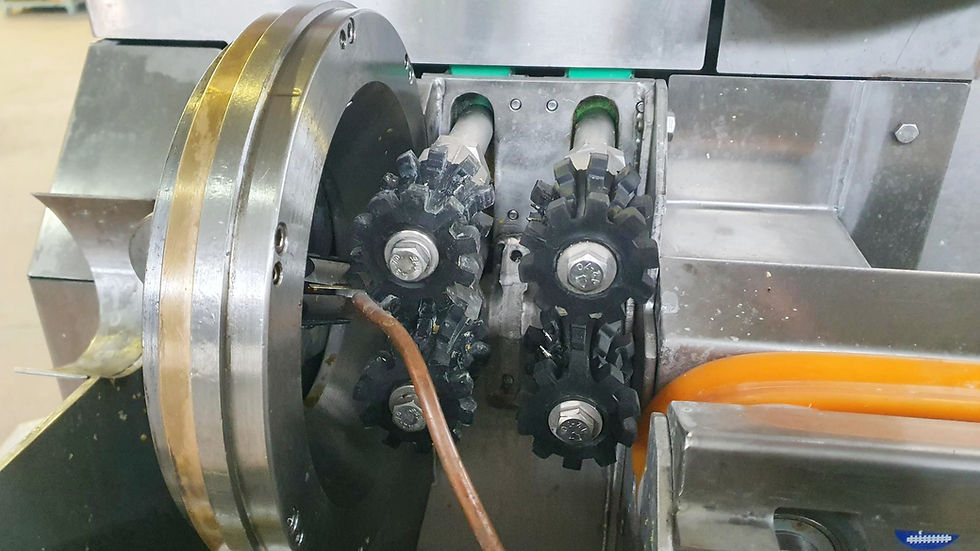

Response: Most competitors use the low-cost 'spinning head' (sıvama) method. In this process, the material thins out towards the edges, gets fatigued, and fails to achieve a perfect spherical shape. We use a 6-segment press-formed welded construction.

Uniform Thickness: Through press-forming, every point of the sheet maintains equal thickness, and the material never gets fatigued.

Safety: All post-welding stages undergo dye penetrant inspection (DPI) for crack detection.

Surface Quality: Internal surfaces are 180 grid, and external surfaces are 80 grid + scotch polished.

Thanks to this meticulousness, the machines we manufactured 40-50 years ago are still running perfectly today. In our engineering vocabulary, 'sheet cracking' simply does not exist.

Feature | Spinning Method (Competitors) | 6-Segment Press-Forming (Our Method - TABANLI) |

Sheet Thickness | Thins out towards the edges. | Uniform thickness maintained at every point. |

Metal Fatigue | Material is overstretched during spinning. | No material fatigue; structural integrity is preserved. |

Form Precision | Difficult to achieve a perfect spherical shape. | Provides a flawless and perfect spherical form. |

Durability | High risk of hairline cracks within 3-5 years. | 40-50 years of trouble-free operational life. |

Prospective Client: "Product burning on the walls is a major issue. Is your agitator equipped with scrapers, and do they cover the entire surface?"

Response: Absolutely. Our agitator features hinged, plate-type food-grade Teflon scrapers. As the mixer rotates, the back-pressure from the product forces the scrapers against the heating jacket, ensuring no spot is left untouched. This prevents any burning or sticking. Since the pressure adjusts itself automatically based on the product’s density, wear is kept to a minimum. Should they need replacement, standard Teflon material can be sourced locally and easily installed.

Prospective Client: "We often face calcification in the condenser due to cooling water. Does the heat exchanger lose efficiency over time? Is it hard to clean?"

Response: We’ve solved this in our flagship 130 cm Vacuum Boule models. Our condenser is a horizontal multitube heat exchanger made entirely of AISI 304 stainless steel. The cooling water flows through the tubes. It features gasketed, flanged covers on both ends. If calcification occurs, you simply open the covers and clean the tubes with ease. Your equipment will never "go deaf"; it maintains peak performance for decades.

Prospective Client: "What about visibility? Once the sight glasses fog up from the inside, we can't see the process."

Response: Our sight glasses come with a built-in internal washing system. Here’s the smart part: it uses the condensate water from the steam jacket. This means no external water is introduced into the system, preserving both hygiene and the product's concentration levels. You get a clear view with zero risk of contamination.

"An Unwavering Passion for Engineering Since 1974."

These systems, manufactured with great precision by our founder half a century ago, continue to operate today with the same initial efficiency. For us, every machine is the product of half a century of experience and a promise of quality passed down from father to son.

Comments