How Industrial Corn Husker Machines Improve Frozen Food Production

- Jan 27

- 2 min read

Maximize Your Husking Efficiency: Why Tabanli Corn Huskers Are the Perfect Fit for US Fields

In the heart of the American Corn Belt, uptime isn't just a goal—it’s a necessity. When harvest season hits, US growers and seed processors need machinery that works hard, stays reliable, and fits seamlessly into their existing workflows.

At Tabanli, we understand that investing in new equipment often comes with a major concern: "Will I be able to find parts, and will it work with what I already have?" The answer is a resounding yes.

Seamless Integration: Built for the American Standard

The biggest hurdle for US operators when considering international machinery is the "proprietary parts" trap. We’ve eliminated that barrier. Tabanli Corn Huskers are engineered with global compatibility in mind.

Our husking rolls are designed to be fully compatible with standard US husker specifications. This means:

Interchangeability: Our rolls can be used in your existing US-made husking beds.

No Spare Parts Stress: Because we adhere to industry-standard dimensions, you aren't tethered to overseas shipping for every minor component. You can source compatible replacement rolls and parts right here in the USA.

Zero Downtime: Keep your operation running with the peace of mind that your maintenance team already knows how to handle these systems.

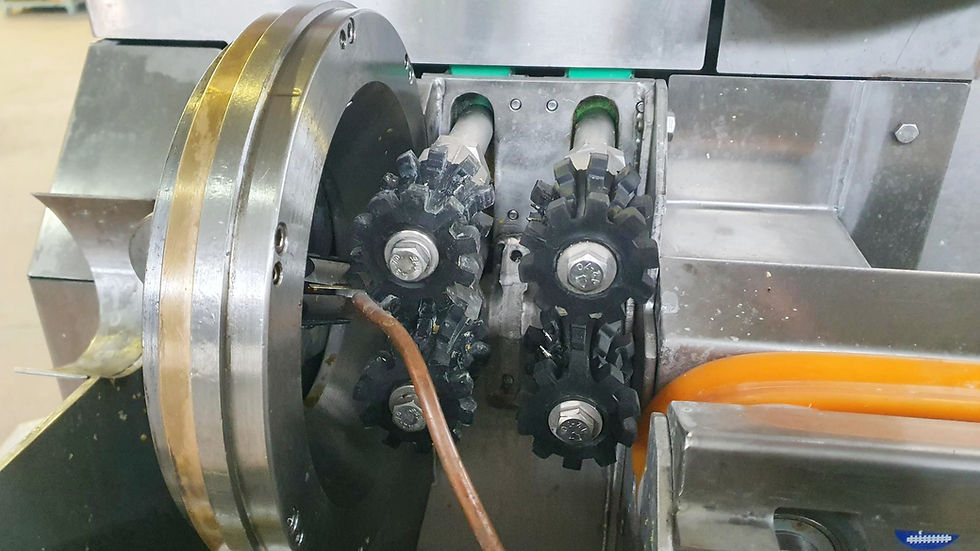

Precision Engineering Meets Rugged Durability

Beyond compatibility, Tabanli brings a level of technical precision that elevates harvest quality. We don’t just husk corn; we protect the integrity of your yield.

Key Technical Highlights:

High-Capacity Throughput: Engineered to handle high volumes without sacrificing husking quality, ensuring your processing line never becomes a bottleneck.

Gentle Handling Technology: Our roll configurations are optimized to minimize kernel damage (mechanical injury), which is critical for seed corn producers where germination rates are everything.

Adjustable Precision: Easily fine-tune the pressure and timing of the husking bed to account for varying moisture levels and hybrid types.

Heavy-Duty Construction: Built with high-grade steel and reinforced bearings to withstand the 24/7 demands of a peak US harvest.

Efficiency That Translates to ROI

Every percentage point of "clean husk" and every hour saved on maintenance adds directly to your bottom line. By combining the robust engineering of Tabanli Corn Huskers with the convenience of US-standard compatibility, we offer a solution that feels local but performs at a world-class level.

Whether you are upgrading a single line or designing a new processing facility, Tabanli provides the bridge between innovative European engineering and American field-proven reliability.

Ready to upgrade your harvest line? Explore our full range of technical specifications and find the right model for your operation at our Corn Huskers product page.

Comments